Want to learn about the manufacturer of your labeling machine?

Want to learn about the manufacturer of your labeling machine?

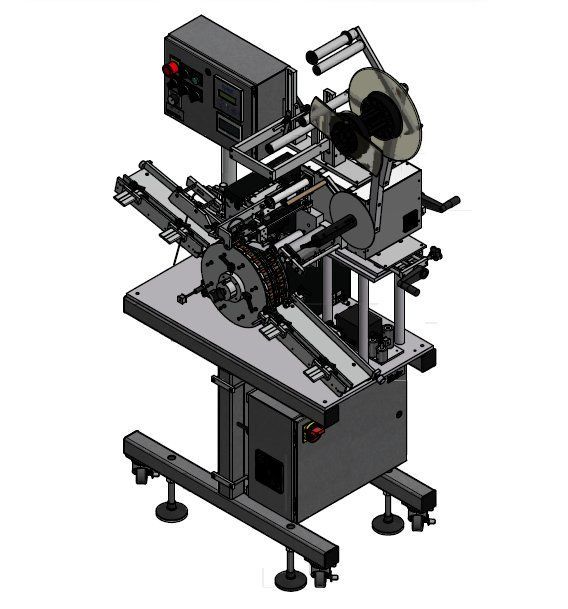

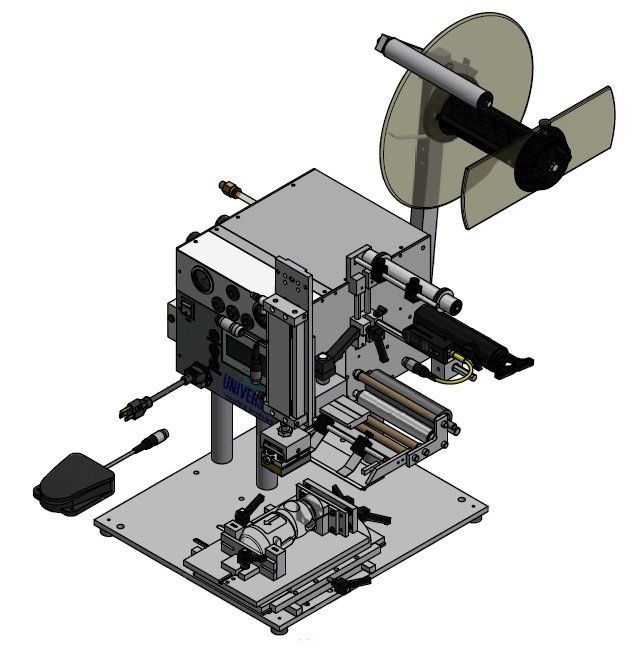

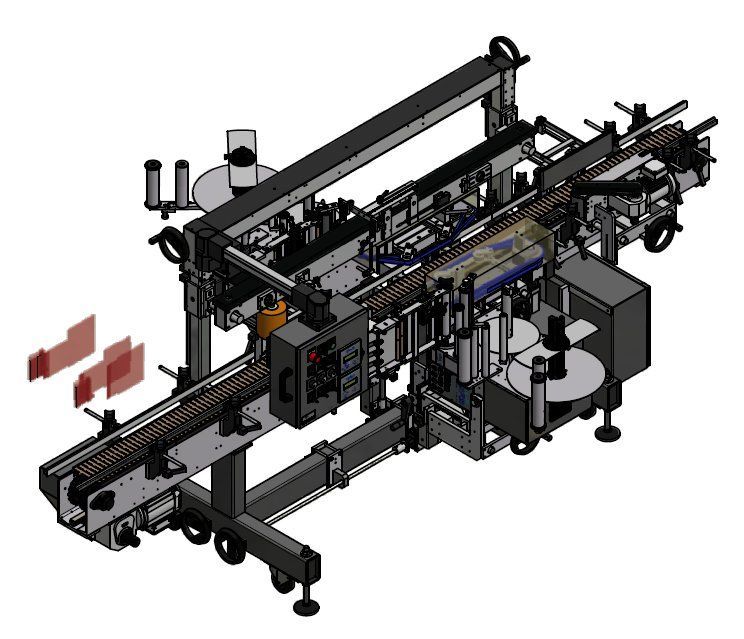

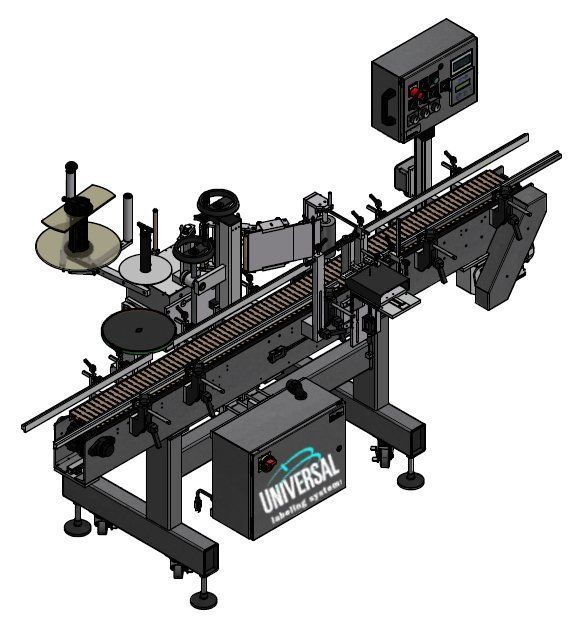

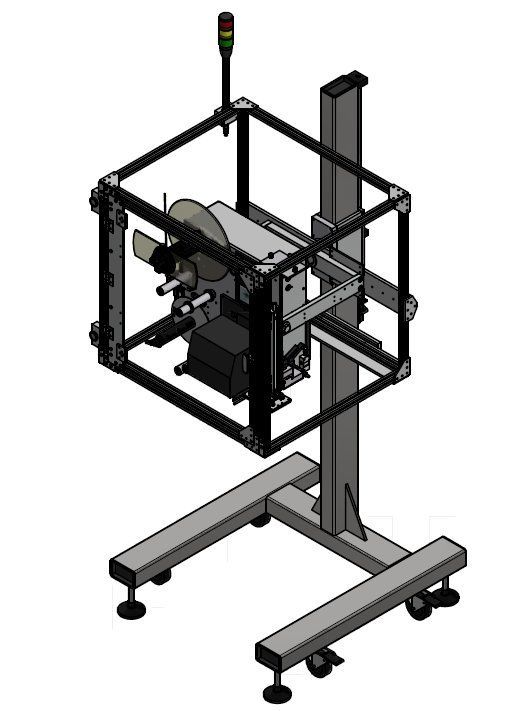

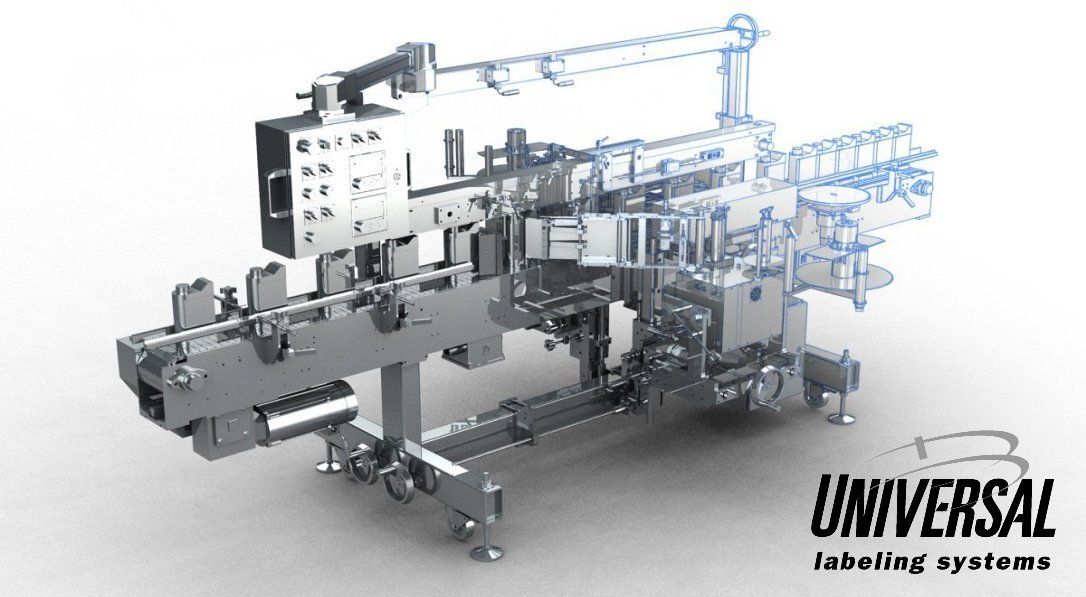

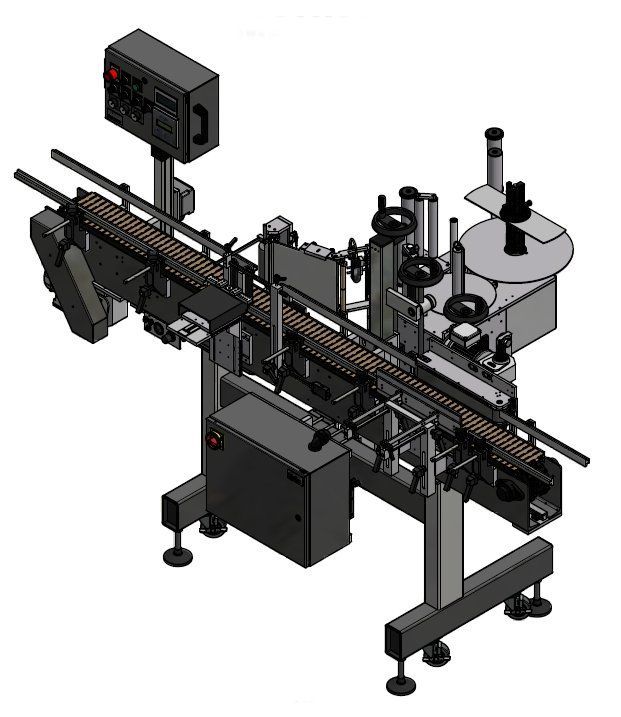

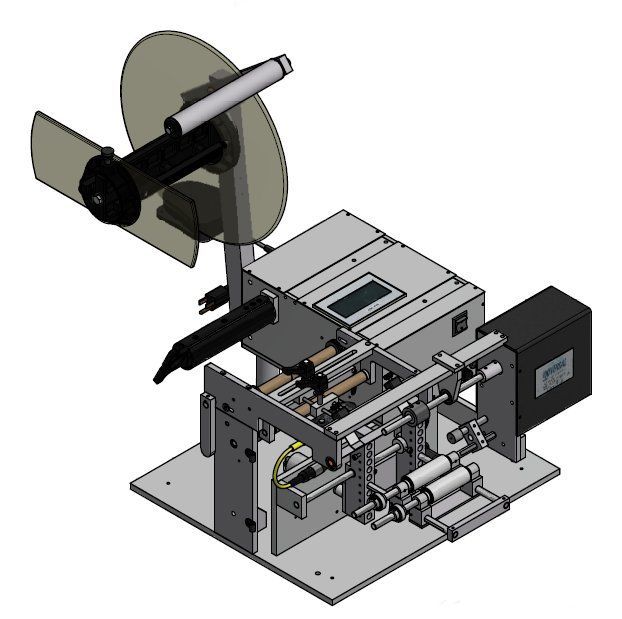

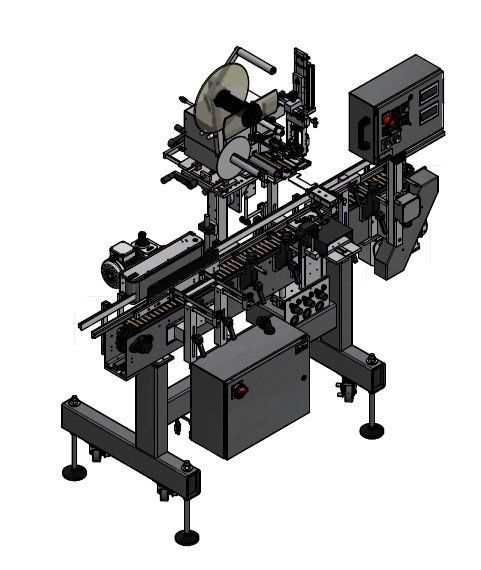

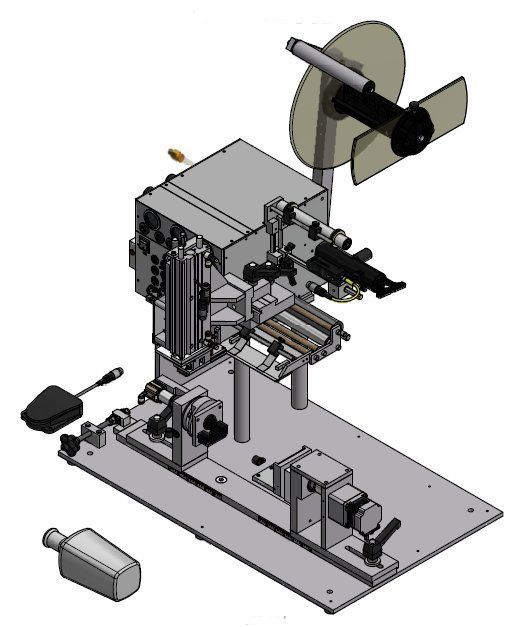

At Universal Labeling Systems, we take pride in being the leader in pressure sensitive labeling machines. Our made-to-order labeling applications include Bottling, Cannabis, craft beer, dairy, food, health & beauty, and pharmaceuticals just to name a few. We build our labeling machines to the needs of your application, providing you the solution, whether that is product identification or decorative labels. Since 1984, we have designed and built labeling equipment that fulfills your needs, from low volume table top labeling machines, to high speed automatic labeling systems, whether your labels are preprinted or thermal transfer print & apply labels.

Want to learn about labeling machines?

Your labeling needs can be solved by answering three key questions. One, what is the ongoing volume needed to be labeled? The determining factor is 6,000 units per day. 6,000 or less is generally the range for a semi-automatic labeling machine, whereas more than 6,000 units per day moves into the range for a more automated labeling solution. Two, what is the shape of your product, and more importantly, is it conducive to automation? For example, a small bottle can be easy to automate, whereas an odd-shaped container may not. Three, how are your products handled and labeled today? This is to determine your current level of automation today, and how much change is possible within your packaging and labeling process. The answer to these three questions can assist us in providing you the options and solutions available to you and your organization.

How can I get started?

The first step is to introduce you to a factory trained expert, a distributor in your area who can be “hands on” in visually inspecting your needs. Our experienced distributors will expand upon the three key aforementioned questions by performing a site survey to determine what type of labeling machine is right for you. We are so confident in our evaluations that we make this pledge to you, “All labeling machines by Universal Labeling Systems, Inc. carries a 30-day performance guarantee. Upon notifying ULS, if your labeling machine does not perform as stated in your quotation, and within 30 days of shipping, Universal Labeling Systems will make every attempt to correct it. If Universal Labeling Systems is unable to meet the specified performance as outlined in the quotation, we will take your machine back and reimburse you in full.”

INTERNATIONAL

Phone 1+ 727 327 2123

mbieda@universal1.com